For BEPS HVAC capital planning, we hear commercial building owners across Maryland and Washington, D.C. asking the same question:

What do the Building Energy Performance Standards (BEPS) mean for my HVAC systems and capital plans?

BEPS is not just a reporting exercise. It changes how you plan, operate, and reinvest in mechanical systems over the next 10 to 15 years. For owners and portfolio managers, that connects directly to budgets, net operating income (NOI), asset value, and how competitive your buildings look to tenants and buyers.

The good news is the work that improves BEPS compliance often improves reliability, comfort, and predictability.

We’ll walk through five key considerations for D.C. and MD BEPS when it comes to HVAC capital planning:

- Why HVAC is usually the fastest path to BEPS improvement

- The Maryland and D.C. timelines that matter for planning

- How to prioritize buildings across a portfolio without a long study

- Where controls and sequencing typically outperform “replace everything”

- How to build a roadmap leadership supports

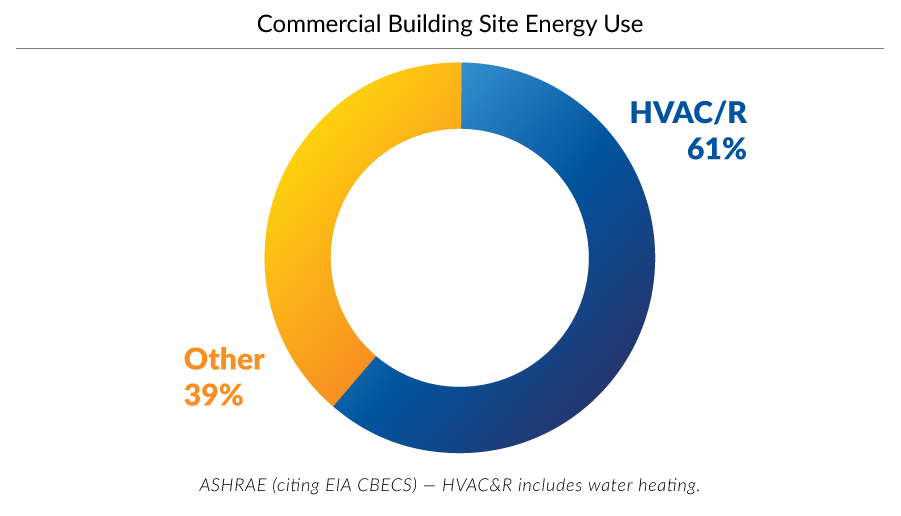

Why HVAC is the Fastest Path to BEPS Improvement

In most commercial buildings, HVAC is the dominant energy load. That is why BEPS planning quickly becomes HVAC planning.

ASHRAE notes that HVAC&R accounts for about 61% of commercial building site energy use (including water heating), citing U.S. EIA CBECS data. (ashrae.org)

But there is a trap here. When standards tighten, it is easy to jump straight to major replacements. In practice, many portfolios can show meaningful progress first by improving how equipment runs, not just what equipment you have.

“Most retrofit wins come from helping equipment run less or perform more efficiently.”

– Justin Ritthauler, Engineer, Havtech

Owner takeaway: Treat HVAC as the lever, but start with the levers inside HVAC (controls, schedules, sequences, ventilation strategy) before you assume you need a full replacement cycle.

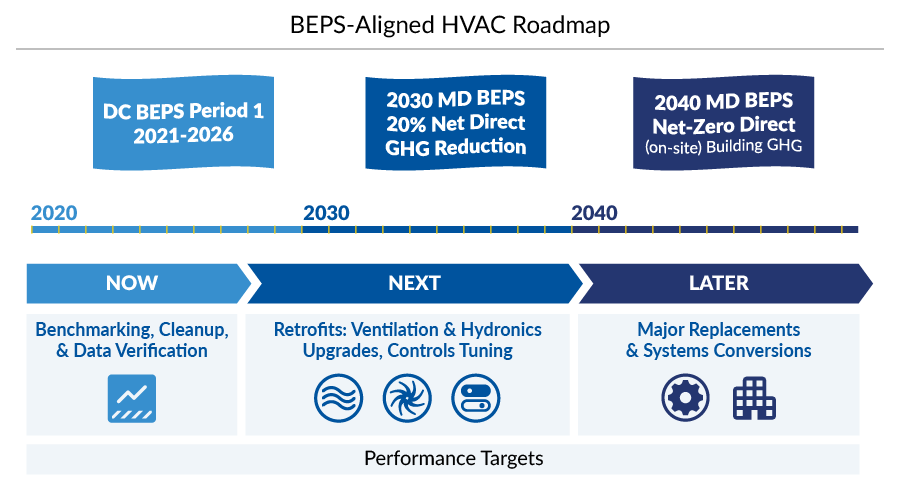

Maryland and D.C. BEPS Timelines for Capital Planning

Your best HVAC decisions line up with the BEPS compliance timeline.

Maryland BEPS

The Maryland’s BEPS program focuses on “covered buildings,” generally 35,000 square feet or larger (excluding parking).

The program starts with benchmarking first, then performance targets later. The Maryland Department of Energy (MDE) starts annual benchmarking in 2025, with performance targets starting in 2030, and guiding buildings toward net-zero direct emissions by 2040.

Maryland also requires recurring third-party verification (not a one-time event).

“BEPS starts with data, not equipment. When the benchmarking is right and the rules are clear, you can make planned decisions about HVAC and capital projects instead of panicking.”

– Chet Knaup, President, Spectrum Energy

Quick note for mixed portfolios: Maryland’s program has evolved with exclusions and jurisdiction-specific rules (for example, Montgomery County has its own requirements). Make sure you confirm which rules apply to each property before you finalize a roadmap.

D.C. BEPS

In D.C., the District of Columbia Department of Energy and Environment (DOEE) establish BEPS standards every six years (“BEPS Periods”). Buildings that do not meet the standard enter a five-year compliance cycle (with the first cycle receiving special timing treatment in earlier rulemaking).

For applicability, DOEE’s guide notes BEPS Period 1 applies to privately owned buildings ≥50,000 SF (and District-owned buildings ≥10,000 SF), with thresholds decreasing in future periods.

Owner takeaway: The compliance timeline is long enough to plan, but only if you start with accurate benchmarking and an honest view of mechanical risk.

Portfolio HVAC Risk Matrix

This does not need to be in-depth for every building. Start with a practical portfolio view and sort properties into “where do we look first?”

Choose the first 3–5 buildings to review by identifying buildings affected under Maryland and D.C. rules (coverage + timeline). Then overlay mechanical risk (failure likelihood, comfort, and inefficiency risk). This approach avoids the “we found out when it broke on the hottest day” scenario across multiple properties at once.

Quick Building and Equipment Checklist

Begin with a short screening for each covered building:

- Age and efficiency of major equipment (chillers, boilers, RTUs, heat pumps)

- Control system age, consistency, and override culture

- Ventilation strategy and how it matches today’s occupancy

- Hydronic condition (pumps, valves, balance, delta-T issues)

- Comfort hot spots and recurring complaints

- Known reliability issues and deferred maintenance

Risk level: low, medium, high

| Risk | Typical profile | Priority actions |

| Low | Newer or recently upgraded systems | Optimize schedules, verify ventilation control, confirm benchmarking inputs |

| Medium | Mixed-age systems, partial upgrades | Target controls tuning, VFD opportunities, focused repairs, light retro commissioning |

| High | Older, inefficient, end-of-life equipment or chronic issues | Deeper assessment, phased capital plan, replacement strategy aligned to BEPS deadlines |

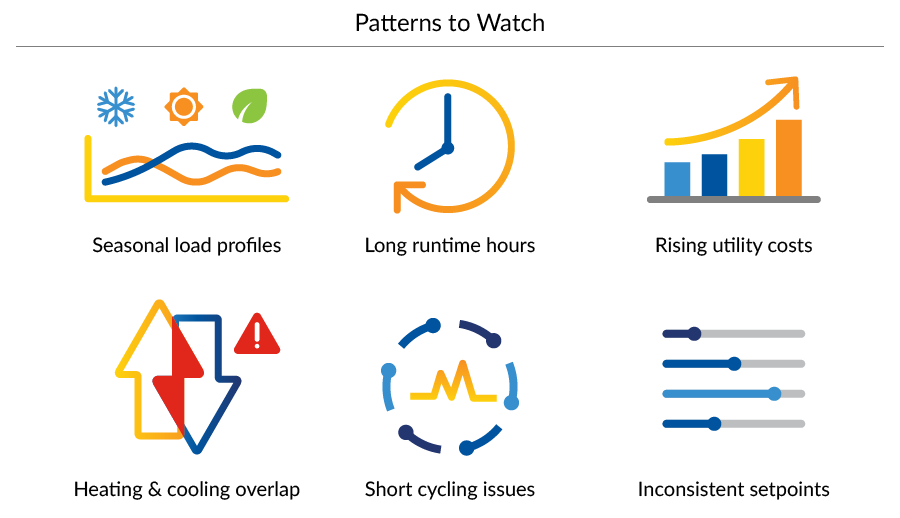

Find Quick Wins with Performance Data

Once your benchmarking is organized, move beyond equipment labels and look at how systems perform over time.

Runtime patterns that signal waste

- Seasonal load profiles that do not match occupancy

- Long runtime hours for fans, pumps, and compressors

- Rising utility use with no clear occupancy change

- Simultaneous heating and cooling

- Short cycling that suggests control or sizing problems

- Inconsistent setpoints across zones

Example: Two buildings can have similar rooftop units (RTUs) on paper, but one is running harder because schedules never changed after a tenant shift, or because zones are fighting the central system. Fixing that can create measurable progress without major disruption.

Fix Controls and Sequencing First

Ask an experienced retrofit engineer where to start and you rarely hear “replace everything.” You usually hear “fix how it runs.”

Practical control and sequencing steps that often pay off fast:

- Update schedules so equipment follows real occupancy, not a guess from ten years ago

- Add HVAC building automation systems to improve performance

- Align outside air control with current requirements and actual building use

- Rebalance hydronic systems so water goes where it is intended

- Coordinate zone control with central operation so the building is not fighting itself

- Add or tune variable speed on fans and pumps where appropriate

These steps can reduce energy use, improve comfort, and sometimes extend useful equipment life, which helps you time replacements more strategically.

Build a 10–15 Year HVAC Capital Roadmap Aligned to BEPS Cycles

Controls and tuning will only take some buildings so far. As standards tighten across cycles, certain assets will need larger upgrades.

0–24 months: Low-disruption improvements

- Clean-up operations: schedules, setpoints, resets, lock out bad overrides

- Controls tuning and sequence fixes (stop simultaneous heat/cool, stabilize runtime)

- Ventilation strategy updates aligned to occupancy and requirements

- Hydronic “foundational fixes”: balancing, valve issues, delta-T problems

- Targeted repairs that improve reliability (not “nice to have” projects)

2–6 years: Targeted retrofits and mid-life upgrades

- Controls modernization (standardize BAS, add trending/analytics where justified)

- VFDs on fans/pumps and better control strategies to use them effectively

- DOAS/ventilation upgrades where ventilation is driving load or comfort issues

- Heat recovery where it fits the building profile

- Focused component refresh: pumps, valves, economizer fixes, sensors, actuators

- Retro-commissioning packages across multiple sites (repeatable scope)

6–15 years: Major replacements and electrification planning

- Plant replacements/rightsizing (boilers, chillers, cooling towers)

- RTU / heat pump replacement cycles (including cold-climate strategies as needed)

- Electrification pathways (where it makes sense): heat pump boilers, VRF/HP systems, hybrid approaches

- Envelope/loads coordination if it meaningfully changes equipment sizing

- Long-lead planning: electrical service capacity, distribution, controls integration

The key to portfolio planning is to turn “projects we should do” into a ranked plan by building.

Evaluate projects by:

- BEPS compliance impact and timing

- Operating expense reduction and NOI stability

- Tenant comfort risk reduction

- Ability to bundle similar work across sites for pricing and execution efficiency

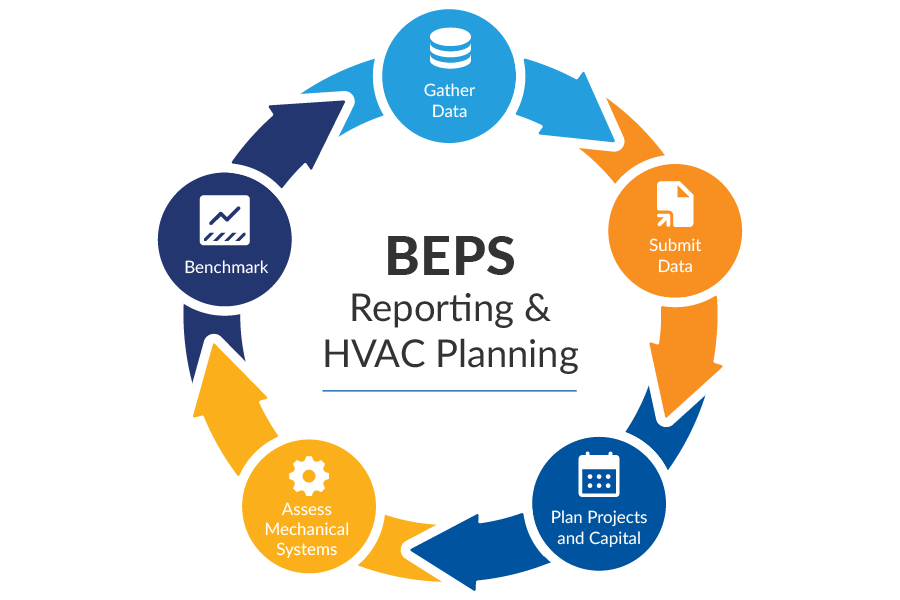

Keep Benchmarking and Mechanical Planning Connected

Most BEPS efforts split into two tracks that must stay connected:

Track 1: Compliance and benchmarking

- Confirm coverage and timelines

- Clean Portfolio Manager data

- Submit required reporting and verification on time

Track 2: Mechanical and capital planning

- Assess system condition and operational performance

- Identify control strategy improvements

- Build a phased project plan that can be delivered

When these tracks are separated, owners either over invest too early or under invest until deadlines force them to panic. When they are connected, BEPS becomes a planning tool.

Key takeaways

- BEPS turns HVAC from a background system into a performance driver because HVAC often dominates energy use in commercial buildings.

- Start with data and timelines, then prioritize buildings by BEPS exposure and mechanical risk.

- Controls and sequencing typically deliver the fastest measurable progress, before major replacements.

- A 10–15-year roadmap helps you avoid surprise capital hits and plan upgrades that protect NOI.

Get a portfolio-level starting point, then decide which buildings deserve deeper engineering.

About the author

Tim Dorman

Innovative Solutions Director, Havtech