A renovation at The Nature Conservancy’s headquarters decreased required chiller capacity by 120 tons while improving indoor air quality.

Instead of increasing outside air and driving up system size, the project paired advanced filtration with a more efficient HVAC design strategy. Cleaner air, lower cooling demand, and a mechanical solution that fit real renovation constraints.

The Design Question

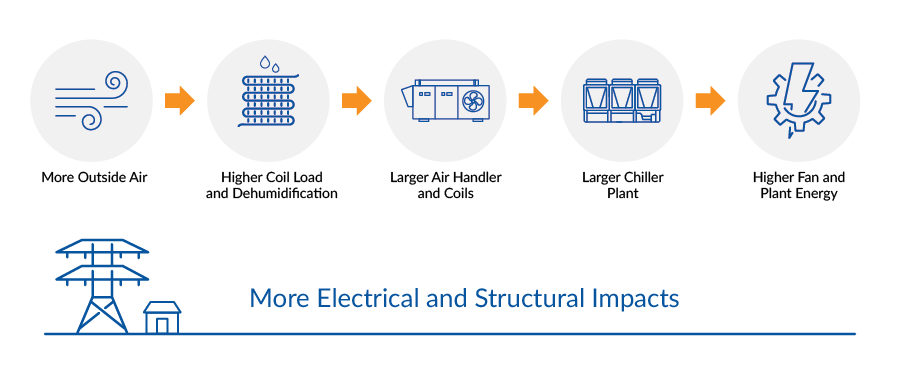

Improving IAQ often comes down to one decision: how much outside air to bring in?

More outside air can be effective, but in renovations it can also increase cooling demand and push equipment sizing higher than the building’s budget or infrastructure can comfortably support. The goal is not simply more ventilation. The goal is clean air with a mechanical solution that stays efficient, buildable, and right-sized.

The Nature Conservancy Project Overview

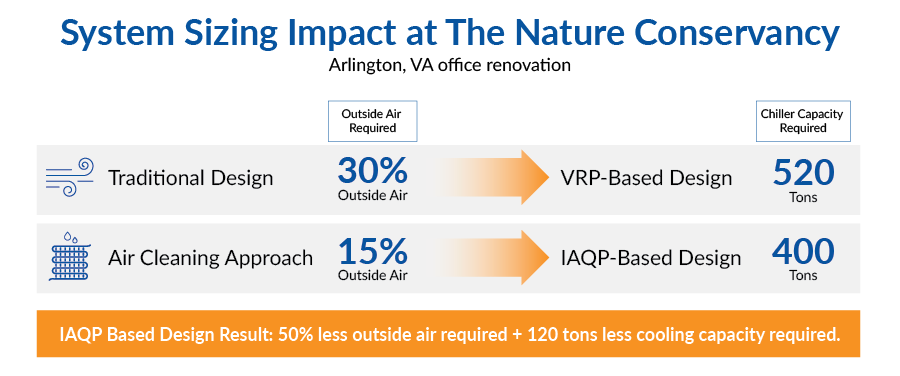

The Nature Conservancy’s eight-story building was undergoing major renovations. With a traditional HVAC design approach, the building would have required:

- A 520-ton chiller

- Large air handlers to process 30% outside air

- Significant electrical and structural investment to support the system size

Rather than increasing outside air volume, Havtech engineers recommended a filtration-based strategy to scrub and recirculate indoor air using sorbent filter air cleaners, paired with an HVAC design to reduce cooling load.

Each floor’s central mechanical room was equipped with two air cleaning modules. This allowed the building to reduce its outside air requirement by half, from 30% to 15%, without sacrificing air quality.

That change had a direct sizing impact. Instead of requiring a 520-ton chiller, the building only needed a 400-ton unit. The 120-ton reduction lowered equipment costs, avoided structural upgrades, and cut long-term operating expenses.

This approach reflects a broader point:

Ventilation improves IAQ, but it is not the only lever, especially when energy, infrastructure, and budget constraints matter.

Using the ASHRAE 62.1 Indoor Air Quality Procedure

How the terms relate

|

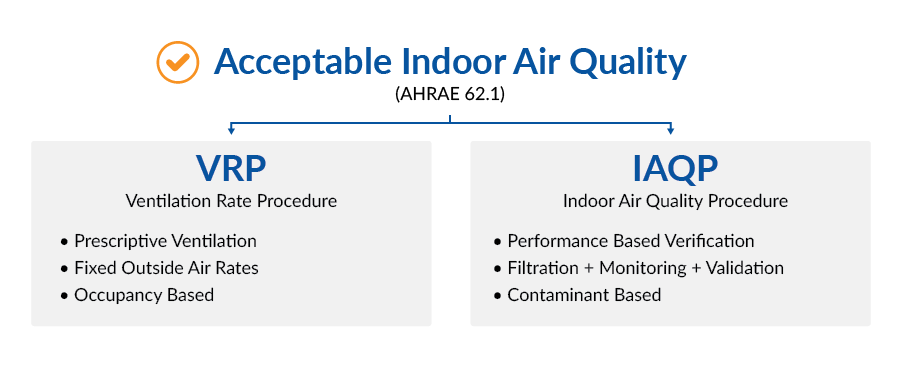

ASHRAE Standard 62.1 is the baseline most teams use to measure acceptable indoor air quality in commercial buildings.

It offers two compliance paths:

- The Ventilation Rate Procedure (VRP), which prescribes minimum outside air rates based on space usage and occupancy.

- The Indoor Air Quality Procedure (IAQP), a performance-based alternative that allows reduced outside air when air cleaning and monitoring, can verify acceptable IAQ. (ASHRAE)

More outside air can improve IAQ, but it isn’t always the most efficient or feasible approach for renovations or constrained buildings. IAQP offers a performance-based alternative: maintain acceptable IAQ by controlling and verifying contaminants through enhanced filtration and real-time monitoring, so ventilation isn’t the only tool.

Compared with the Ventilation Rate Procedure (VRP), which prescribes minimum outside air rates based on occupancy and space type, IAQP provides flexibility that can help avoid oversized systems and unnecessary energy use.

The goal remains the same – acceptable indoor air quality. What changes is the method.

Indoor Air Quality and the Larger Indoor Environmental Quality Picture

IAQ is the cleanliness and safety of the air, typically measured by levels of carbon dioxide, volatile organic compounds, particulates, and humidity.

It matters, but it is one part of the full occupancy experience.

IAQ sets up the baseline for health and safety, but Indoor Environmental Quality (IEQ) is what occupants experience.

IEQ also includes thermal comfort, acoustic comfort, lighting and daylighting, air freshness, and perceived health and productivity.

Takeaway

You can meet IAQ standards and still have a space people complain about because it is drafty, noisy, or smells off. Designing for IEQ means designing how spaces are experienced.

Indoor Environmental Quality and Building Occupants

For schools, the U.S. Environmental Protection Agency (EPA) has published research showing that schools without a major maintenance backlog have higher average daily attendance:

- 4-5 students per 1,000.

- Lower annual dropout rate of 10-13 students per 1,000. (EPA)

For office environments, peer-reviewed research has reported that poor indoor air quality can decrease productivity, with field validation studies showing effects ranging from six to nine percent on aspects of office work performance. (PubMed)

The energy cost of increased ventilation can be small compared to estimated productivity impacts. Peer-reviewed studies led by Harvard T.H. Chan School of Public Health researchers report that:

- Doubling ventilation in office buildings costs less than $40 per person, per year across the climate zones investigated.

- An estimated eight percent improvement in cognitive performance.

- That level of improvement was estimated to be equivalent to roughly $6,500 in productivity per person, per year.

Related success story: See how Alice West Fleet Elementary (Arlington, VA) reduced outside-air load while maintaining excellent IAQ in a net zero energy design.

Good, Better, Best IEQ Strategy

Improving IEQ does not require a complete system overhaul. Use a phased approach based on building conditions, budget, and goals.

Good

- Install MERV 8 filters on all air streams and MERV 13 filters on all outside air inlets.

- Replace filters quarterly.

- Verify and balance airflow to meet design requirements.

- Design to ASHRAE 62.1 ventilation standards.

Better

- Use sorbent or electronic filtration in return or recirculated air streams to reduce outside air volumes while maintaining proper IAQ.

- Standardize one technology across a building portfolio to simplify maintenance.

- Add a basic contamination monitoring system for visibility.

Best

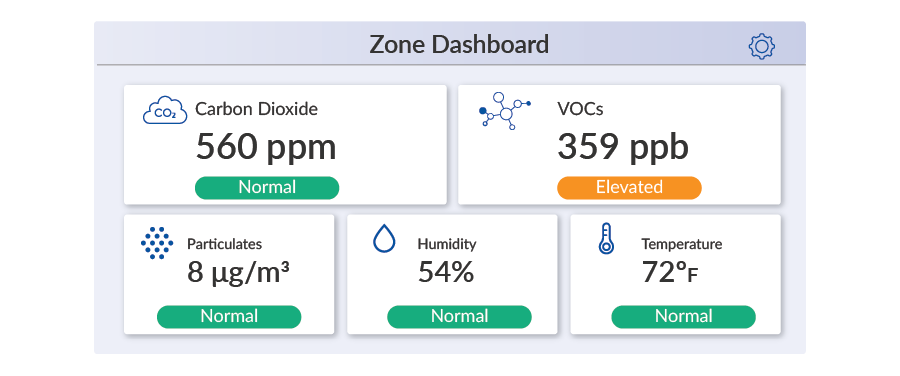

- Install real-time IAQ monitoring dashboards that track carbon dioxide, VOCs, particulates (PM1.0, PM2.5, PM10), formaldehyde, humidity, and temperature.

- Add ionization or UV-C systems for on-demand pathogen mitigation.

- Design for compliance with ASHRAE Standard 241 for infectious aerosol control protocols (ASHRAE).

Indoor Air Quality Monitoring Dashboards

An IAQ monitoring dashboard tracks real-time conditions in every zone, including:

- Temperature and relative humidity

- Carbon dioxide

- VOCs

- Particulate matter (PM1.0, PM2.5, PM10)

- Formaldehyde

- Ion levels (where ionization is installed)

The data doesn’t lie. If you monitor it, you can prove (and improve) it.

If the IAQ dashboard flags elevated VOC levels in a zone, the facilities team knows where to look and how to respond. Real-time visibility helps prioritize maintenance and response and provides transparency for both tenants and owners.

If you want to tie IAQ data into a building-wide view of performance, modern building automation can bring HVAC equipment and sensors into unified dashboards and alerts. HVAC building controls and automation

Start Upgrades High in Impact Spaces

Not every area of a building offers the same return when it comes to IAQ and IEQ upgrades.

Start in high-occupancy, low-exhaust spaces such as conference rooms, classrooms, offices, cafeterias and dining areas, auditoriums, lobbies, and fitness centers.

These areas typically lack continuous exhaust and can benefit from air cleaning, monitoring, and improvements.

The Case for IEQ ROI

For many building owners and operators, the biggest barrier to implementing an IEQ strategy is budget justification.

The Nature Conservancy project provides a clear first-cost example. Downsizing from a 520-ton chiller to a 400-ton unit reduced upfront equipment costs, eliminated the need for structural reinforcements, and cut long-term utility bills.

When facility teams pair outcomes like this with measured data, decisions get easier. Real-time VOC levels, airflow trends, and filter performance give stakeholders confidence to approve the next phase.

How Havtech Supports an Indoor Environmental Quality Roadmap

The Nature Conservancy project is proof that, with the right filtration, monitoring, and HVAC design strategy, buildings can achieve healthier indoor environments while reducing system size and energy demand.

Key takeaways

- The Nature Conservancy project reduced outside air from thirty percent to fifteen percent and right-sized cooling from 520 to 400 tons.

- IAQP in ASHRAE 62.1 is a performance-based path that can allow reduced outside air when IAQ is verified and maintained with enhanced filtration and real-time monitoring. (ASHRAE)

- IAQ is measurable air cleanliness and safety, but IEQ includes how people experience the space, including comfort, acoustics, and lighting.

- A Good, Better, Best strategy helps teams improve IEQ without requiring a full system overhaul on day one.

- Monitoring data helps facility teams justify investment decisions with real numbers rather than opinions.

See if IAQP can right-size your next retrofit

Share your building type, current outside air assumptions, and renovation constraints. We’ll outline two pathways (VRP and IAQP), identify where filtration and monitoring can reduce load, and map the next steps for design and implementation.

Request an IAQP Feasibility Review

About the author

Tim Dorman

Innovative Solutions Director, Havtech