Category: Articles

Why Radiated Noise Consideration Deserves a Role in HVAC System Design

When designing comfortable indoor environments, acoustics often don’t get the attention they deserve, especially during the HVAC design phase. Yet, radiated noise from mechanical systems can directly impact occupant comfort, satisfaction, and even productivity.

This is especially true in open ceiling applications, where ductwork, terminal units, and structural elements are intentionally left exposed. Without traditional ceiling tiles and plenum spaces to absorb or mask sound, even low levels of radiated noise can become disruptive.

Understanding radiated vs. discharge noise

In HVAC systems, we typically think about noise moving through the ducts (discharge noise). But in many projects, the bigger challenge is radiated noise: sound emitted through the casing of the terminal unit itself, especially fan-powered boxes.

Radiated noise:

- Travels directly into occupied spaces

- It is harder to attenuate after install

- Can be a common source of post-occupancy complaints

Why open ceilings raise the stakes

Open ceilings are becoming more common across building types, from high-rise offices to universities, hospitals, and retail. They offer aesthetic and architectural advantages, but they also eliminate one of the most effective tools for managing sound: the acoustical ceiling tile.

With fewer barriers between HVAC equipment and occupants, the noise from mechanical systems becomes more noticeable and more important to get right during design.

What to consider early in the process

To reduce the risk of acoustical issues and rework:

- Evaluate radiated sound data, not just discharge values, when selecting terminal units

- Consider NC (Noise Criteria) ratings in the actual context of the space especially in open plans or hard-surface environments

- Ask manufacturers about orientation options for return air openings, which can affect both layout and acoustics

- Include acoustical performance as part of the value conversation with clients—not just thermal or energy efficiency

Tools that can help

Designing for acoustical performance doesn’t have to mean overcomplicating the system. More manufacturers are responding to these challenges with terminal unit options built for NC-sensitive spaces and open ceiling layouts.

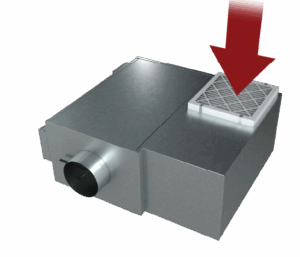

If you’re working on a project where sound is a known risk, there are new resources worth exploring. Price Industries offers an ultra-quiet series fan powered box called the FDC-TFK.

Find out more here:

Price Industries FDC-TFK Brochure – Ultra Quiet Fan Powered Terminal Unit

Price Industries FDC-TFK fan powered terminal unit featuring optimized design for minimal radiated noise in exposed ceiling environments.

Get Expert Insight On Your Next Project

Contact Havtech for help with acoustical comparisons, editable spec language, or product demos.

At Havtech, we support engineers designing for both performance and occupant experience, because a quiet system is one that’s done right.

Why Damper Placement Shouldn’t Be Overlooked in Low-Temp Reheat Design

A Closer Look at Terminal Unit Performance

In HVAC system design, details matter, especially when your goal is high efficiency with low-temperature reheat systems.

For decades, most single-duct VAV terminal units have placed the damper upstream of the reheat coil. While this configuration is familiar and still widely used, when applied to low-temp hydronic systems (120°F and below), it can introduce performance losses that aren’t always obvious at the design stage.

One recent innovation, the Price SDV-Vantage, takes a different approach by relocating the damper downstream of the coil to improve efficiency and airflow performance.

New to single-duct systems? Price Industries has a quick overview:

Damper position vs. coil performance

Recent third-party studies and testing show that placing the damper upstream of the coil can lead to:

- Uneven airflow across the coil face at part-load

- Up to 13% loss in heating capacity, even at steady airflow

- Temperature stratification in the discharge duct

- Reduced accuracy of zone control and sensor feedback

These issues are especially problematic when working with condensing boilers or heat pump systems, where water temperatures are lower and thermal performance margins are tighter.

Downstream damper placement option

Moving the damper downstream of the coil helps maintain uniform airflow across the heat exchanger. Testing has shown this approach can lead to:

- Improved heat transfer across all damper positions

- Reduced fluid flow requirements, lowering pump energy use

- More consistent discharge air temperatures

- Fewer issues with sensor control logic due to stratified temperatures

This configuration addresses a common but often-overlooked efficiency gap in low-temp reheat design.

Price Industries Vantage cross section showing the downstream damper.

Is this relevant to your next project?

If you’re designing HVAC systems for schools, offices, or healthcare facilities, here are a few questions to consider:

- Are you specifying VAV terminal units to perform using 100–120°F hot water supply conditions?

- Do your system sequences depend on accurate downstream temperature sensing or stable airflow control?

- Is your team trying to reduce pumping energy, system air pressure drop, or improve boiler return temps?

If so, damper placement should be evaluated just like any other critical component.

It’s not a replacement, It’s a design option

Upstream damper configurations still have their place. They’re well-understood, reliable, and appropriate for many conventional hydronic designs.

This isn’t about replacing one standard with another, it’s about aligning the terminal unit design with the performance goals of today’s low-energy systems.

How Havtech Supports the Engineering Process

Our team helps engineers:

- Evaluate VAV unit specifications for part-load and low-temp performance

- Review airflow measurement and control strategies

- Support submittal review, mockups, and performance modeling

- Provide insight into how real-world configurations impact operation and energy goals

Want to Evaluate Your Current Approach?

Our engineers are available to discuss current specs, provide sample data, or walk through test results in more detail.

It’s 6:15 AM on a scorching Thursday in late August. The custodial team at Jefferson Middle School just turned on the lights when the first call came in. Temperatures in the west wing are too hot!

The HVAC unit serving that part of the building shut down overnight, and now numerous classrooms are approaching 85°F before students even arrive. Teachers will be calling soon; nurses are on standby for heat-related issues, and the principal has requested immediate status reports and is bracing for a wave of complaints.

For Jim, the facility director, this isn’t just uncomfortable; it’s a crisis. He’s scrambling to mobilize rental chillers, allocate portable fans, and track down replacement parts. All the while, he knows this failure could have been prevented.

In school environments, maintaining HVAC systems isn’t just about comfort, it’s about creating a healthy environment that supports learning and operational stability. For facility directors managing dozens (or hundreds) of classrooms across a district, it’s a high-stake balancing act: tight budgets, aging infrastructure, growing air quality expectations, and constant pressure to “just keep things running.”

With a strategic, lifecycle-based HVAC approach, facility managers can go from firefighting to forward planning. This shift cuts costs, saves time, and creates healthier spaces for students and staff.

Source: Pacific Partners Consulting Group & ENERGY STAR

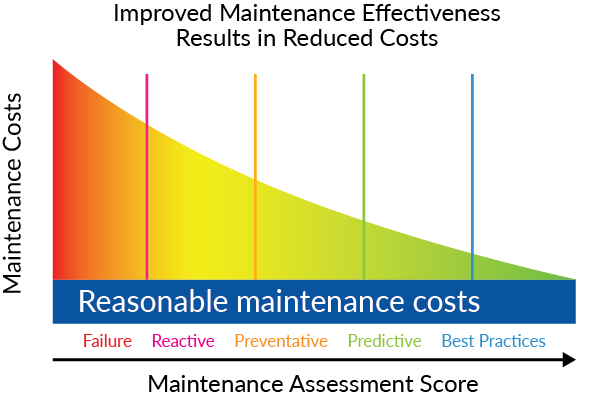

THE TRUE COST OF REACTIVE HVAC MAINTENANCE

Emergency repairs may solve an immediate issue, but they come at a premium not just in dollars, but in disruption

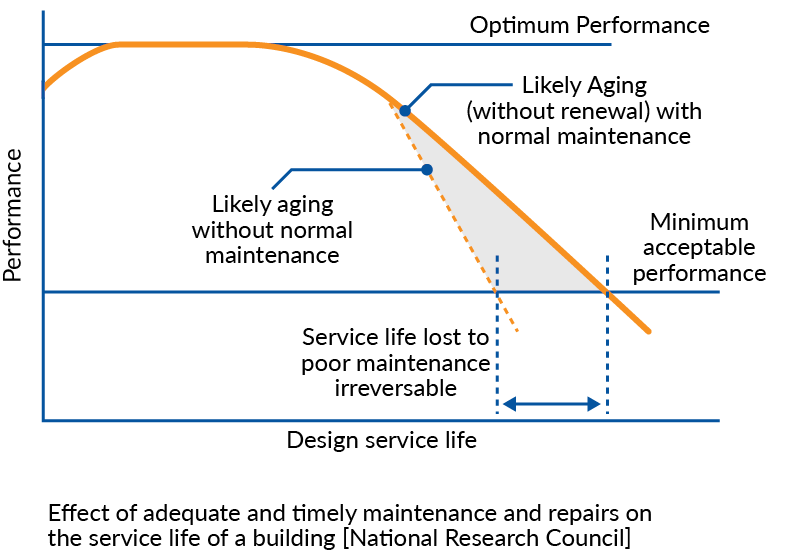

Studies from the U.S. Department of Energy and ENERGY STAR show that deferring HVAC maintenance shows a greater risk of downtime during peak weather months.

What are the effects?

- More health-related complaints and student and staff absenteeism due to poor indoor air quality

- Higher volumes of comfort complaints, disrupting focus and impacting learning outcomes

- Unexpected rental and mobilization costs for temporary cooling equipment

- Shortened equipment life cycles, resulting in frequent and costly replacements

The lesson? Proactive maintenance isn’t a luxury, it’s a cost-saving necessity.

A proactive K-12 HVAC maintenance strategy goes beyond filter changes and seasonal tune-ups.

Plan & Track: Know what you have and stay on schedule

- Create an Accurate Equipment Asset Inventory

Document all your HVAC units, their age, condition, service history, and manufacturer-recommended maintenance milestones. This becomes the foundation of an effective long-term plan. - Build a Preventive Maintenance Plan

Follow manufacturer guidelines and any applicable state or local requirements (such as Maryland’s IAC Preventive Maintenance Task List) to reduce unexpected failures and keep systems operating efficiently. - Leverage a Computerized Maintenance Management System (CMMS)

Use a CMMS to automate work orders, track service dates, manage parts, and maintain digitized records. This makes audits easier and reduces administrative headaches.

Train & Monitor: Detect problems before they disrupt

- Invest in Staff Training

Educate your internal maintenance teams on how to identify early warning signs and make informed service calls. When possible, enroll them in manufacturer-specific training programs with your local representative. - Add Predictive Maintenance & Performance Monitoring

Use tools like oil and vibration analysis, sensor-based alerts, and equipment trend tracking to spot wear or inefficiencies early before breakdowns occur.

Update & Recalibrate: Maintain long-term efficiency

- Recommission HVAC Systems Regularly

Even high-performing systems drift over time. Recommissioning ensures they meet current demands and operate as efficiently as when first installed, especially after major upgrades or system changes. - Benchmark Your Energy Use

Track utility data using ENERGY STAR Portfolio Manager or similar tools to compare your energy use with peer buildings, uncover trends, and justify system improvements or replacements.

Partner Strategically: Choose the right support

- Hold Vendors Accountable to Your Goals

Partner with a provider who understands the unique challenges of K-12 environments and offers proactive strategies not just reactive service. A strong partner helps reduce downtime and improve overall system performance.

Source: www.iac.maryland.gov

With rising utility costs, more districts are viewing HVAC performance through a cost-reduction lens. HVAC system upgrades for schools like variable speed drives or control retrofits can often pay for themselves over time, especially when supported by utility and state driven incentives, rebates, or grants.

An energy-focused partner can help you identify such opportunities, secure funding and build a case for internal approvals needed for project operations or capital funding investments.

Improving Indoor Air Quality in K-12 Schools

Indoor Air Quality (IAQ) is one of the most critical and often overlooked components of a healthy school environment. According to the U.S. Environmental Protection Agency (EPA), poor IAQ can negatively affect the health, performance, and attendance of both students and staff.

“… students in well-maintained facilities often outperform those in substandard buildings by 5 to 17%.”

− Glen I. Earthman,

School Facility Conditions and Student Academic Achievement, 2002

See how this school’s net zero design has excellent indoor air quality and reduced maintenance. The challenge was to meet stringent indoor air quality requirements, which often necessitate more outside air, while minimizing energy impact to get to net zero energy.

How to follow IAQ best practices:

- Ensure adequate ventilation rates in accordance with ASHRAE standards

- Keep HVAC components clean and dry to prevent microbial growth

- Use high-efficiency filters appropriate for the system design

- Inspect and maintain outside air intakes regularly

By integrating these practices into your HVAC strategy, you help protect student health and promote better academic outcomes.

The EPA’s “IAQ Tools for Schools” program emphasizes a proactive, team-based approach to indoor air management.

Rely on a Partner You can Trust

Havtech works with K-12 school systems in the mid-Atlantic region to implement HVAC programs that reduce stress on facilities teams and create safer, healthier buildings.

Whether you need a partner for a system rebuild, ongoing maintenance, help navigating compliance, or guidance on energy-saving upgrades, we’re here to support your team.

Interested in learning how to improve your reliability and save costs?