Tag: Price

Why Radiated Noise Consideration Deserves a Role in HVAC System Design

When designing comfortable indoor environments, acoustics often don’t get the attention they deserve, especially during the HVAC design phase. Yet, radiated noise from mechanical systems can directly impact occupant comfort, satisfaction, and even productivity.

This is especially true in open ceiling applications, where ductwork, terminal units, and structural elements are intentionally left exposed. Without traditional ceiling tiles and plenum spaces to absorb or mask sound, even low levels of radiated noise can become disruptive.

Understanding radiated vs. discharge noise

In HVAC systems, we typically think about noise moving through the ducts (discharge noise). But in many projects, the bigger challenge is radiated noise: sound emitted through the casing of the terminal unit itself, especially fan-powered boxes.

Radiated noise:

- Travels directly into occupied spaces

- It is harder to attenuate after install

- Can be a common source of post-occupancy complaints

Why open ceilings raise the stakes

Open ceilings are becoming more common across building types, from high-rise offices to universities, hospitals, and retail. They offer aesthetic and architectural advantages, but they also eliminate one of the most effective tools for managing sound: the acoustical ceiling tile.

With fewer barriers between HVAC equipment and occupants, the noise from mechanical systems becomes more noticeable and more important to get right during design.

What to consider early in the process

To reduce the risk of acoustical issues and rework:

- Evaluate radiated sound data, not just discharge values, when selecting terminal units

- Consider NC (Noise Criteria) ratings in the actual context of the space especially in open plans or hard-surface environments

- Ask manufacturers about orientation options for return air openings, which can affect both layout and acoustics

- Include acoustical performance as part of the value conversation with clients—not just thermal or energy efficiency

Tools that can help

Designing for acoustical performance doesn’t have to mean overcomplicating the system. More manufacturers are responding to these challenges with terminal unit options built for NC-sensitive spaces and open ceiling layouts.

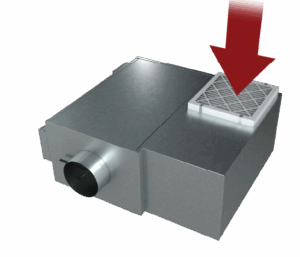

If you’re working on a project where sound is a known risk, there are new resources worth exploring. Price Industries offers an ultra-quiet series fan powered box called the FDC-TFK.

Find out more here:

Price Industries FDC-TFK Brochure – Ultra Quiet Fan Powered Terminal Unit

Price Industries FDC-TFK fan powered terminal unit featuring optimized design for minimal radiated noise in exposed ceiling environments.

Get Expert Insight On Your Next Project

Contact Havtech for help with acoustical comparisons, editable spec language, or product demos.

At Havtech, we support engineers designing for both performance and occupant experience, because a quiet system is one that’s done right.

HVAC Systems have seen a lot of changes over the last decade. This includes energy reduction goals, calls for decarbonization, reduction in fossil fuel use, embodied carbon, and net zero stretch goals. This presentation will explore the key drivers, i.e., carbon emissions, global warming, and the role Hydronic systems can play in potentially alleviating some of the challenges.

✅ PDH Eligible