Hydronic Heating and Cooling Systems, Reliable Comfort

Delivered through Morin Hydronics, a Havtech company with decades of expertise in HVAC hydronic solutions and efficient heat transfer.

End-to-End Support for Your Hydronic Projects

From design and equipment selection to installation support and maintenance, we tailor each system to your facility’s needs.

Whether for new construction or replacement projects, our specialists guide you through load calculations, equipment selection, piping layouts, and commissioning. Helping you reduce risk and ensuring long-term performance.

Products

High-Performance Hydronic Equipment for New and Replacement Systems

Energy efficient commercial HVAC systems that meet your building’s needs. From heating and cooling to air distribution and specialty equipment, we help you select solutions that deliver comfort, efficiency, and reliable performance.

Trusted by Industry Leaders. Chosen to Represent the Best.

Get Started With the Right Hydronic Heating System

Avoid delays and uncertainty. Our experts help you select, design, and install a hydronic system that fits your facility and long-term goals.

Support That Keeps Your HVAC Systems Running Like They Should

Every building needs a plan. Whether you’re building one or managing one, a reliable HVAC maintenance plan and access to commercial HVAC repair services make all the difference.

You get answers fast and support that’s built around your priorities.

Local Experts, Backed by Regional Strength

With personnel across the Mid-Atlantic, you get support from people who know your market, your codes, and your project demands.

Hydronic Systems FAQ

Choosing the right HVAC equipment can get complicated, but it doesn’t have to be. We’re here to help you make the right call.

How can I improve the efficiency of my hydronic heating and cooling system?

Improving hydronic system efficiency starts with regular maintenance and modern components. Upgrading to variable-speed pumps, condensing boilers, and high-efficiency heat exchangers can greatly reduce energy use. Integrating building automation controls can also optimize loop temperatures and equipment staging for long-term savings.

How does replacing a cast iron boiler with a condensing fire tube boiler improve efficiency?

Upgrading to a condensing fire tube boiler can significantly increase system efficiency while reducing energy costs. These boilers recover heat from exhaust gases, achieving higher thermal efficiency than traditional cast iron designs. They also feature a smaller footprint, lower operating weight, and greater design flexibility — ideal for both retrofit and new construction projects.

What flue construction materials are recommended for condensing boilers?

For condensing boiler systems, stainless steel or polypropylene flue materials are typically recommended. These materials meet UL standards and are designed to resist corrosion from condensate. The best choice depends on the specific boiler application, such as emergency generators, condensing, or non-condensing systems.

What options do I have to replace an existing heat exchanger?

Current heat exchanger designs allow for lower approach and pressure drop to increase system energy efficiency by lowering loop temperature and pump head requirements. Existing heat exchanger performance may be compromised due to fouling, dirt or debris clogging plates, or leaks. Performance can be improved by installation of a new plate pack with no piping changes and minimal downtime.

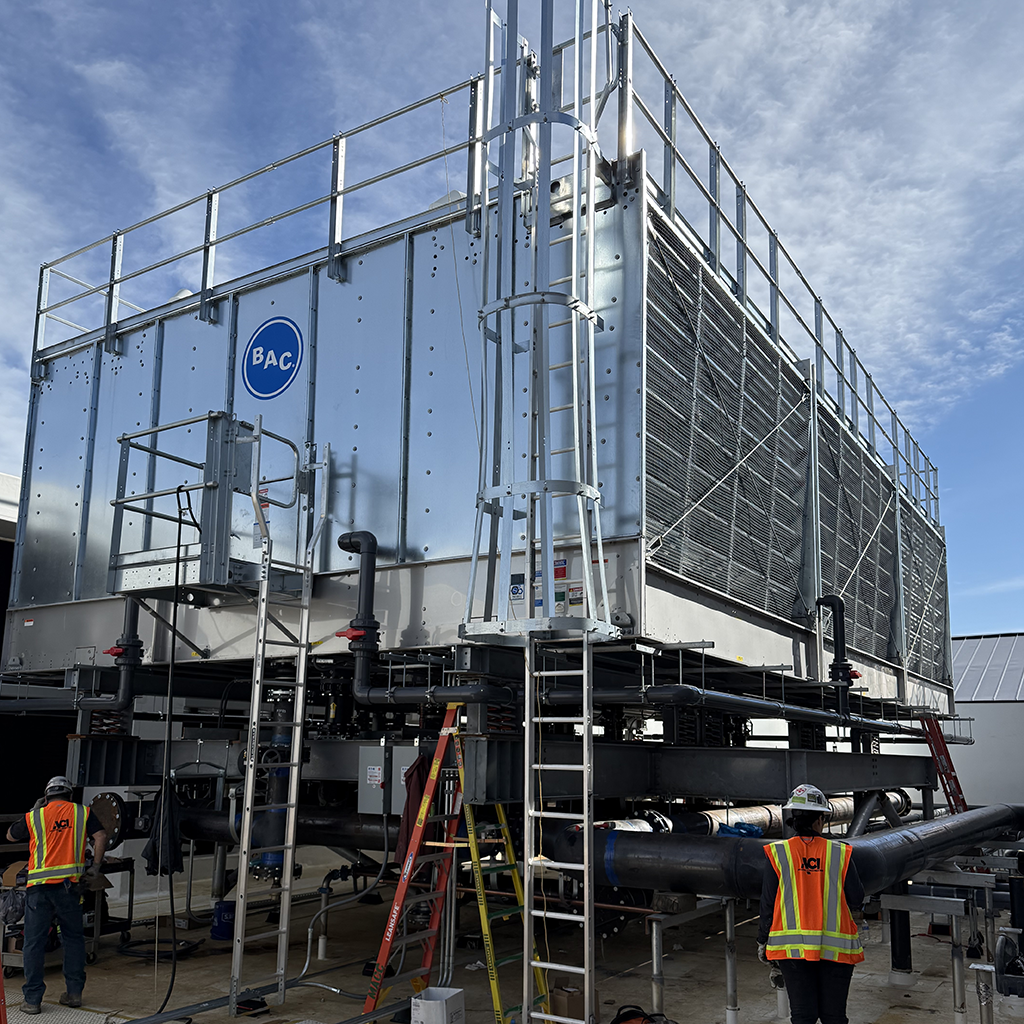

What is the advantage of a water-cooled heat rejection system?

Water-cooled heat rejection using open cooling towers, closed-circuit cooling towers, or adiabatic dry coolers have lower energy consumption, smaller footprint, and lower sound levels than air-cooled systems.

What should I consider when selecting a cooling tower replacement?

Choosing the best cooling tower replacement depends on several factors, including existing steel supports, electrical service, piping layout, sound requirements, and architectural constraints. It’s also important to consider load, energy efficiency, loop temperatures, and total installed cost. Havtech can help evaluate and specify a system that fits your site conditions and performance goals.

Can I retrofit vertical stack fan coil units without major building modifications?

Yes. Many existing vertical stack fan coil units can be retrofitted or upgraded without extensive infrastructure changes. Options include replacing internal components or the entire chassis while keeping the existing cabinet in place. Havtech offers low-profile, custom-sized fan coil solutions that fit within your existing space for a faster, more cost-effective upgrade.

Find the Right Hydronics System for Your Project

Let’s get your project moving with the right hydronics system, installed the right way.